Chitra, Bhavnagar, Gujarat

- GST NO. : 24AKLPM1107D1ZP

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

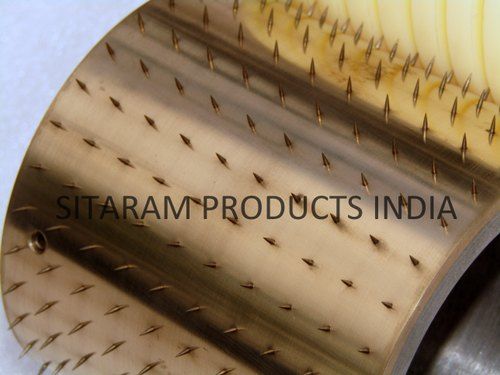

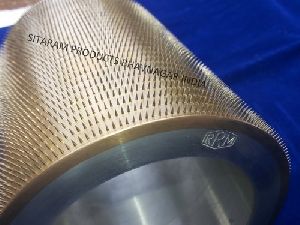

| Type | Pinned |

| Material | Brass |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Pin Diameter

0.3 mm

Shape

Round

Usage

Industrial

Surface

Polished

Brand Name

SP

Payment Terms

L/C, D/A, D/P, T/T

Product Details:

| Minimum Order Quantity | 10 Piece |

| Material | Brass |

| Brand | SP |

| Shape | Round |

| Use | Spinning Machinery |

Other Details

- Design of perforation rollers and the perforating unit as per customer''s requirement is available to our company.

- First time in India our country started to manufacture the following type of rollers.

- Needles in perforation rollers can be arranged in different patterns like the linear pattern, crossed pattern and diamond pattern.

- Supporting Nylon or P.U. based rollers are manufactured at our company for perforating machinery.

- Needle density up to 28 needles/ square cm can be obtained.

- All of our rollers can be supplied as a single unit, or as a series of pattern-matching inter-locking units for lengthier applications.

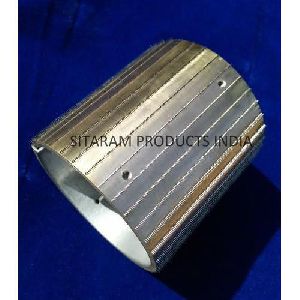

- Lengthy Rollers are often replaced at a very high cost, so we convert it into pinned segments that can be modified to fit any machine. The locating holes on each roller match precisely, so there are no interruptions in pattern and, by using this method, should only one roller be damaged in the process, only that unit needs repair or replacement, rather than the complete unit.

- Heat-treated and the best quality pins are used for hot perforation as well as cold perforation.

- Rollers are made up of high graded G.M. or brass according to the material to be perforated.

- With many years of experience in precision drilling, our highly skilled staff take pride in producing these quality parts with absolute accuracy.

Request

Callback

Callback

Additional Information:

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer),D/P,D/A,Other

Looking for "Pinned Perforating Roller" ?

Piece

Explore More Products